What’s Inside?

Disclaimer: Please remember that this not only voids your three year warranty, but it's also significantly more dangerous than just playing around inside a PC when it's on – you have the full power of a wall socket at your fingertips and potentially charged capacitors that can give a lethal shock.It only takes the usual four screws in the lid to get inside and unlike the Corsair TX750W and Thermaltake Toughpower QFan 650W, this has no plastic piece that hinders airflow (even though we were told this plastic creates a negative pressure underneath to direct the air in and around we’re still unconvinced that it is the best solution).

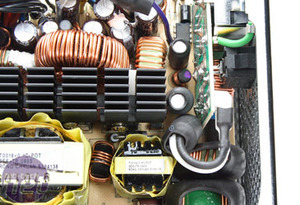

Two rows of black aluminium ribbed (to increase surface area, not pleasure) heatsinks sit in line with the exhaust in the case to funnel the hot air out. The components around them are also positioned to sit in line with the airflow too.

The capacitors are not solid aluminium capped, but we’re yet to see more than just a few smaller ones in a PSU that are. Enermax uses KY and KTZ branded capacitors produced by Nippon Chemicon/United Chemi-Con and the bulk electrolytic capacitors are made by Panasonic – this is true for the entire Modu and Pro 82+ range. The smaller capacitors are rated to 105˚C but the larger capacitors are rated to just 85˚C because they are placed in more open air, right underneath the fan.

When questioned about its MTBF rating, Enermax made this statement to bit-tech:

“MTBF is 100K hours @ 25˚C which is demonstrated or say calculated by inputting ALL components per US MIL-STAND-217F, Transformers, MOSFETs, Electrolytic Capacitors (E/C) for primary and secondary caps, rectifier, resistors and etc. If it is converted to Bell-Core, US commercial standards, MTBF of our PSU product would be 45K hours. In addition, the cooling fan must be excluded as some responsible manufacturer’s state in their specs sheets. The life span of the ball bearing system used in a cooler(s) traditional two ball bearing can't ever last 100K hours. Nevertheless, 40˚C ambient temp at 100 percent rated loading is the standard we apply for agency approval and verified in the test reports endorsed by those agencies we applied to.”

Some have claimed that the internal typology looks similar to the older Liberty and Infiniti ranges, however Enermax explains that it has seen a significant upgrade:

“First of all, the typology has already been upgraded to a two double forward circuitry, whereas the Liberty adopted the latest forward topology three years ago. With the jump on typology implemented on our new series and some minor control circuits, Enermax’s new 82+ series are actually very different from its old models and new models from the competition.

Second, we have been communicating the specs and performance of components inside these PSUs since last year. For example, Japanese SENDUST cores are now used which have a higher magnetic through-put that contributes to higher switching efficiency at a wider range of AC input conditions. Furthermore, the PFC board has been integrated to the master PCB which allows for better airflow compared to the current Liberty and Infiniti products. It's the result that some users have been urging and waiting for quite some time.”

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.